Plastics used in engineering have superior resistance to heat and corrosion, in addition to their already impressive mechanical properties. As a result, engineering plastic parts have found widespread application across a variety of industries. Listed below are some of the more typical application domains. Plastic casings, keyboards, sockets, and other components that are commonly used in electronic products like TVs, mobile phones, and computers are all examples of engineering plastic parts that have seen widespread use in the electronics industry. This includes the use of engineering plastic in the manufacturing of electronic components. Because of their excellent electrical insulation and flame retardant properties, engineering plastics can help ensure the safety and stability of electronic equipment.

Hoods, front grilles, door trim panels, and other components are just some of the many applications for engineering plastic parts in the automotive industry, which also have many other applications in the automotive industry. The use of engineering plastics, which benefit from high strength, low density, and resistance to heat, can help reduce the overall weight of automobiles, thereby enhancing both their fuel economy and their level of safety. Industry related to medicineSurgical instruments, medical instruments, and other similar products are examples of the many uses that can be found for engineering plastic parts in the medical industry. Engineering plastics have good biocompatibility and antibacterial properties, which can prevent harm to the human body. In addition, engineering plastics have good chemical resistance and high temperature resistance. Biocompatibility refers to a material's ability to coexist with living organisms without causing any adverse effects.

The industry of home appliancesPlastic components designed for use in engineering also have a wide range of applications in the field of home appliances. These include the kinds of plastic components that are typically found in washing machines, refrigerators, microwave ovens, and other household appliances. Because of their high resistance to heat, corrosion, and wear, engineering plastics are able to fulfill the requirements set forth by home appliances. The building and construction sectorThe construction industry is another sector that makes extensive use of engineering plastic parts. Some examples of their applications in this sector include plumbing pipes, fire doors, sound insulation panels, and many more. Plastics used in engineering have excellent corrosion resistance and weather resistance, and they are able to withstand the effects of environmental factors such as air pollution, sunlight, and rain.

To summarize, engineering plastic parts find widespread application across a variety of industries, including the electronic, automotive, medical, household appliance, and building and construction sectors. The range of applications for engineering plastic parts will continue to broaden as a result of developments in areas such as science and technology as well as ongoing progress in the field of material technology. Beauty equipment is an essential component of the day-to-day lives of people living in the modern era, and spare parts are an essential component of beauty equipment. When it comes to picking out replacement parts for beauty equipment, the material is a very important consideration. So, what kind of material do you online machining services recommend for the replacement parts of beauty equipment?.

To begin, it is necessary for us to gain an understanding of the qualities that are necessary for the spare parts of the beauty equipment. The replacement components for the beauty equipment have to be able to withstand high temperatures without breaking down, corrosion, oxidation, and wear, at the very least. These characteristics have the potential to ensure the beauty equipment's stability as well as its service life. Titanium alloy is a very good option because it not only has great resistance to corrosion and high strength, but it also has good biocompatibility. This demonstrates that the titanium alloy is not likely to trigger an allergic reaction when it comes into contact with the skin. Titanium alloy, in addition, possesses good mechanical properties. It is resistant to high pressure and tensile force, and it does not easily deform, which means that it can ensure the beauty instrument will continue to function reliably over an extended period of time.

In addition to that, stainless steel is a material that is frequently utilized. Stainless steel not only has high strength but also a high resistance to corrosion, and it also has a good resistance to wear. Because stainless steel is resistant to corrosion caused by acids and CNC Turning Services alkalis, it is commonly used in the construction of beauty equipment. In addition to stainless steel and titanium alloy, another material that sees frequent application is aluminum alloy. As a result of its low weight, high strength, excellent electrical and thermal conductivity, and good electrical conductivity, aluminum alloy is frequently utilized in the production of beauty equipment.

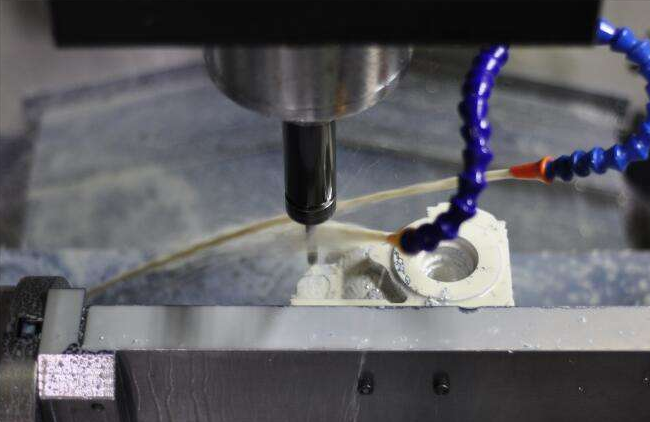

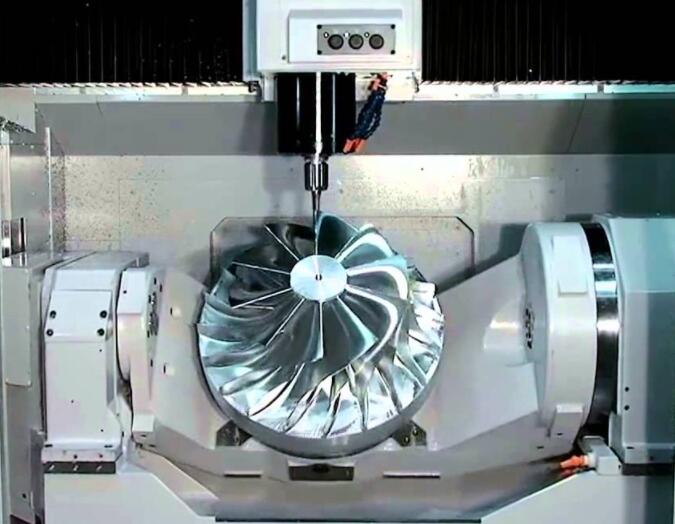

There are a few better options, including titanium alloy, stainless steel alloy, and aluminum alloy. Obviously, the beauty instrument's intended use in addition to the design requirements will determine the type of material that should be used. In order to ensure that the beauty instrument spare parts you purchase are of a high quality and have a long life span, you must pay careful attention to the manufacturing process as well as the material's quality, regardless of which material you decide to use. Machining by computer numerical control (CNC) is a processing method that is both high-precision and high-efficiency. The processing of complicated parts is made possible by controlling the processing machine tool through the use of computer programs. This results in processing that is both highly precise and of consistent quality. This method of processing is appropriate for the mass production of beauty instrument spare parts, and it requires a high level of precision as well as dimensions that remain stable.

Stamping processing involves the use of molds to stretch, bend, shear, and perform other processing methods on plates. This enables the production of a large quantity of parts in a short amount of time and with minimal effort. Stamping is an efficient method of manufacturing components for beauty equipment that have a simple shape and are of a compact size. Some examples of these components include massage heads and masks. Injection molding processing refers to a method of processing in which molten plastic is injected into a mold in order to form the desired object. This method of processing is well-suited for the production of plastic beauty instrument spare parts in large quantities, such as handles, casings, and other similar components. Injection molding is capable of producing parts with high efficiency and at low cost, but it has stringent requirements for the molds themselves.

Thermoforming is a method of processing that involves heating a plastic sheet or film material until it becomes pliable, and then pressing the material into the desired shape using pressure. This method of processing is well suited for the mass production of beauty equipment spare parts that have thin walls, special shapes, and large areas of application, such as facial masks, eye masks, and other similar products. The term "laser cutting" refers to a method of processing that makes use of laser beams to perform the cutting process. This processing method is capable of cutting with both high precision and high speed. This method of processing is appropriate for cutting metal, plastic, and other materials, and it is capable of producing high-precision and consistent-quality spare parts for beauty equipment.